Yesterday’s Access4tech event, organized by EIT Manufacturing and hosted at BPI France Le Hub, brought together industry leaders, innovators, and local policymakers to discuss a single, crucial topic: How do we accelerate innovation in European manufacturing?

The discussions were candid, the insights sharp, and the message clear: The path to a smarter, more competitive, and sustainable industrial future requires a fundamental shift in collaboration, investment, and culture.

Here are the five essential takeaways that every enterprise, startup, and investor in the industrial sector needs to know.

1. Large Enterprises Must Become Innovation Test Beds 💡

Innovation often begins with a great idea in a small office, but it achieves scale on the factory floor. We heard a resounding call for large industrial enterprises to play a pivotal role not just as customers, but as active test beds for Small and Medium Enterprises (SMEs) and startups.

For a young company with a promising technology—be it predictive maintenance, advanced robotics, or a new supply chain solution—gaining access to a real-world, operational environment is invaluable.

By offering their facilities as sandboxes for innovation, large companies gain early access to cutting-edge solutions, while startups get the crucial data and validation needed to perfect their products and achieve commercial viability.

This symbiotic relationship is the engine of rapid industrial change.

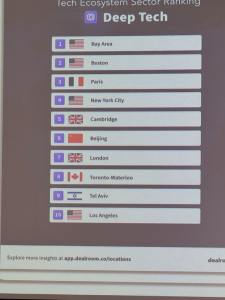

2. Strategic Capital is the Deep Tech Accelerator 💰

The future of manufacturing relies heavily on Deep Tech—the fundamental scientific and engineering breakthroughs that underpin major industrial shifts. These innovations, however, require significant time and capital.

The access4tech event underscored the strategic role of both Venture Capital (VC) and public funds. Their purpose is twofold:

- Financial Support: Providing the patient, long-term capital necessary to commercialize complex, science-based technologies.

- Talent Attraction: Utilizing financial strength to attract and retain the world’s best engineering and scientific minds in key European hubs.

While the emergence of players like Mistral.ai from Paris highlights Europe’s potential, sustained, strategic investment is crucial to maintaining this momentum and scaling innovations into global market leaders.

3. The Global Race Demands Greater Speed ⏱️

3. The Global Race Demands Greater Speed ⏱️

While there’s undeniable talent and money concentrated in major EU hubs, the global reality check is sobering: Europe lags behind the pace of innovation set by the US and emerging Chinese powerhouses.

The session highlighted that the European ecosystem must not only innovate but do so faster. For organizations like BeChained, this means not just adopting new technologies in the supply chain but integrating them with urgency. The global competitive landscape isn’t waiting, and for European manufacturing to secure its long-term future, we must translate our scientific prowess into market dominance with greater alacrity.

4. Overcoming Cultural Barriers to Data-Driven Success ⚙️

It’s often said that culture eats strategy for breakfast, and this couldn’t be truer for industrial digital transformation. While the technology for data-driven manufacturing exists, many industrial manufacturers still face internal cultural challenges to widely adopt it. Resistance to change, siloed data, and a long-standing reliance on traditional methods are common hurdles.

The key to a successful, organization-wide rollout is not to attempt a “big bang” transformation. The key successful factors are to deliver fast and achieve quick wins. By focusing on small, impactful projects—such as optimizing a single machine’s performance or reducing waste in one line—companies can quickly demonstrate return on investment (ROI), build internal champions, and create the proof points necessary to scale adoption across the entire organization.

5. The Cleantech Mandate: Aligning Regulation with Reality 🌿

Europe is undeniably the trailblazer in Cleantech, setting ambitious targets and driving transformation through progressive regulations.

This regulatory push is essential and non-negotiable for a sustainable future.

However, the event’s dialogue also exposed a friction point.

The ambitious regulatory timeline is often crashing into the practical constraints of enterprises’ existing product roadmaps. Manufacturers operate on long cycles. To ensure compliance is a source of competitive advantage rather than a paralyzing burden, there must be continuous dialogue between policymakers and the industry.

So, to ensure regulations are implemented in a way that is challenging yet achievable, allowing companies to successfully integrate sustainability goals into their engineering and investment plans.

The Road Ahead

A clear roadmap: to win the future of manufacturing, we need greater enterprise collaboration, smarter financial support for Deep Tech, a focused acceleration of innovation to compete globally. This is a cultural commitment to quick, data-driven wins. And practical alignment between cleantech mandates and industrial reality.

#Manufacturing #Innovation #DeepTech #DigitalTransformation #SupplyChain #EITManufacturing #Cleantech #Industry40