The terms “AI agent” and “agentic AI” are often used interchangeably, leading to confusion. While both involve artificial intelligence, their applications, particularly in advanced industrial settings like those envisioned by BeChained, highlight a crucial distinction. Understanding this difference is key to appreciating how AI is not just assisting but autonomously governing complex production processes, ushering in an era of green and efficient manufacturing.

What are AI agents?

AI agents are systems designed to perceive their environment, reason using AI models, and take actions to achieve predefined goals. Think of them as sophisticated digital workers. They are typically:

-

- Reactive: they respond to specific triggers or user requests.

- Goal-oriented (specific tasks): they are excellent at performing narrow, often repetitive tasks within programmed boundaries.

- Limited autonomy: their decision-making is largely constrained by their programming, with limited capacity for independent learning or adaptation outside their defined scope.

A common example is a LLM, equipped with tools like a code interpreter, capable of executing specific commands to fulfill a user’s request, such as writing and running code to calculate a Fibonacci sequence. Their utility lies in automating well-defined, straightforward processes.

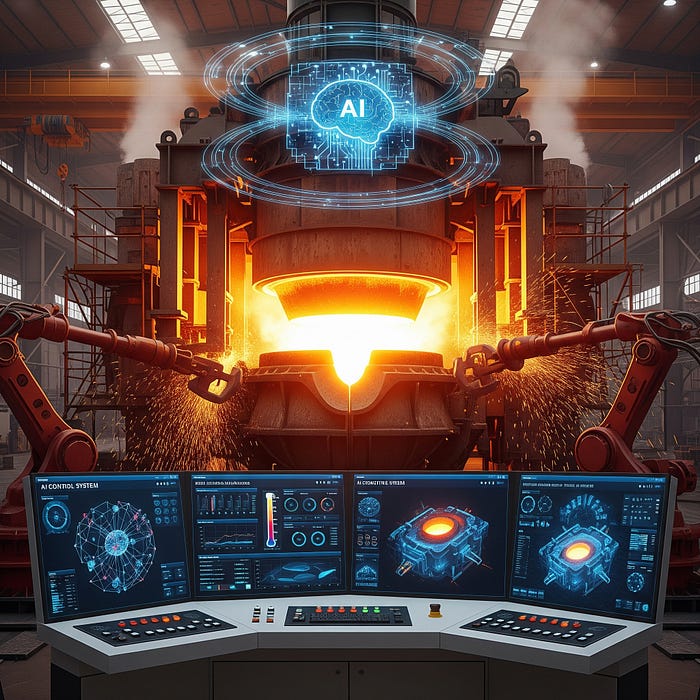

Agentic AI in BeChained applications: autonomous governance for industrial processes

Agentic AI, particularly in the context of BeChained’s industrial applications, represents a far more advanced and transformative approach. This form of AI operates with significant autonomy, making its own decisions, setting sub-goals, and adapting to dynamic situations with minimal human intervention. In BeChained’s vision, agentic AI is the brain behind future green facilities, autonomously governing machines across specific production processes.

while general AI agents can be applied broadly, agentic AI in BeChained is deeply embedded and specialized for the unique demands of industrial manufacturing processes

Agentic AI for BeChained

For BeChained, agentic AI is:

-

- Proactive and autonomous: unlike reactive AI agents, agentic AI systems continuously monitor industrial environments (e.g., water management systems, air compressor systems, thermal processes like plastic injection, re-heating furnaces, enamelling furnaces, grinders, extractor hoods). They identify deviations, predict potential issues, and autonomously initiate actions to optimize performance, energy consumption, and product quality.

- Complex task management: agentic AI systems can orchestrate multiple operations and coordinate different machines or sub-systems to achieve a larger, complex objective. For instance, an Agentic AI system managing a plastic injection process wouldn’t just control temperature; it would also adjust pressure, cycle times, and material flow in real-time based on environmental factors, raw material properties, and desired output quality.

- Adaptive and learning: these systems learn from a wide range of interactions, data streams, and outcomes. They continuously refine their decision-making models to improve efficiency, reduce waste, and enhance operational resilience.

- Domain-specific: while general AI agents can be applied broadly, agentic AI in BeChained is deeply embedded and specialized for the unique demands of industrial manufacturing processes. Its intelligence is tailored to the physics, chemistry, and operational nuances of specific industrial equipment.

BeChained’s vision leverages agentic AI to transform industrial facilities into self-governing, green ecosystems where machines operate with unprecedented autonomy. This shifts the role of human operators from direct control to oversight, fine quality inspection, and strategic product development. Instead of manually adjusting parameters, operators become high-level managers, leveraging their expertise for innovation and addressing highly complex, non-routine challenges that still require human intuition and creativity.

The Critical Distinction

The fundamental difference lies in autonomy, scope, and strategic impact:

-

- AI Agents are tools that execute specific tasks, often initiated by external prompts. They are the building blocks.

- Agentic AI systems are orchestrators, embodying proactive decision-making and adapting complex processes towards overarching strategic goals. They leverage multiple AI agents or modules to achieve broad, autonomous control over critical operations.

In essence, while AI Agents are about automating tasks, agentic AI, as demonstrated by BeChained, is about automating entire processes and achieving autonomous governance of complex industrial ecosystems. This distinction is pivotal as industries move towards smart manufacturing, where AI is not just a helper but a core decision-maker, driving efficiency, sustainability, and continuous innovation.

For more general insights into AI agents vs. agentic AI, you can refer to the article that inspired this post: AI Agent vs. Agentic AI: Understand the Actual Difference.

Some applications

BeChained’s vision of autonomous, green industrial facilities is powered by agentic AI, not just simple AI agents. This means specialized AI systems that aren’t just reacting to commands but proactively making decisions to optimize entire processes.

Here are specific examples of how agentic AI would function in the production processes BeChained specializes in:

-

-

Water distribution systems (WDS):

-

Traditional approach: sensors monitor water quality and flow, alerting human operators to issues i.e. viscosity (in paper manufacturing), pH imbalances (in chemical processes) or leaks, then manually adjust chemical dosing or dispatch maintenance.

BeChained’s agentic AI: an agentic AI system would constantly monitor dozens of parameters (pH, viscosity, chemical levels, flow rates, pressure, energy consumption of pumps, weather forecasts, production demand). It would autonomously:

-

- Predict and prevent: identify patterns indicating potential flow issues and proactively adjust water treatment chemical dosages or filtration rates before quality issues arise.

- Optimize energy: Adjust pump speeds, pressure and flow based on real-time energy prices and facility demand to minimize electricity use.

- Detect & mitigate leaks: pinpoint the exact location of a leak from pressure drops and flow anomalies, autonomously isolate the affected section, and reroute water without human intervention, simultaneously dispatching a repair drone or technician.

- Human role: human operators oversee AI’s performance dashboards, review high-level reports on water system efficiency, and intervene only for unforeseen failures or strategic upgrades to the water infrastructure.

2. Air compressor systems:

Traditional approach: compressors run at fixed speeds or react to pressure drops, leading to energy waste during low demand, or operators manually adjust settings.

BeChained’s agentic AI: the agentic AI monitors air demand across the entire factory, ambient temperature, humidity, compressor health metrics (vibration, temperature, oil pressure), and energy costs. It autonomously:

-

- Dynamic load balancing: optimizes the operation of multiple compressors, adjusting variable speed drives to precisely match real-time air demand, minimizing energy consumption.

- Adaptive predictive maintenance: analyzes subtle changes in vibration or oil temperature to predict potential bearing failure or filter clogging, autonomously managing actuators to balance performance, scheduling maintenance according to production schedule and eventually ordering parts before a breakdown, preventing costly downtime.

- Leak detection & remediation: uses acoustic sensors and pressure decay analysis to detect compressed air leaks, then directs maintenance personnel to exact locations or, in advanced scenarios, initiates automated patching for minor leaks.

- Human role: operators monitor overall system efficiency, receive notifications about upcoming maintenance, and focus on higher-level energy management strategies rather than daily adjustments.

3. Thermal processes (i.e. plastic injection, re-heating furnaces, enamelling furnaces):

Traditional approach: operators manually set temperatures and cycle times based on experience, making adjustments when quality degrades, defects appear or energy consumption is too high.

BeChained’s agentic AI: for a plastic injection molding machine, the agentic AI would monitor raw material viscosity, ambient temperature, mold temperature, injection pressure, melt temperature, cooling rates, and real-time part quality via sensors onboard and integrated vision systems. It autonomously:

-

- Real-time process optimization: adjusts injection speed, holding pressure, and cooling time on a per-shot basis to compensate for slight variations in raw material batches or ambient conditions, ensuring consistent part quality and minimizing scrap.

- Energy efficiency: optimizes heating and cooling cycles to use the least amount of energy, while maintaining quality, learning from on-the-run data, environmental changes, and thousands of production cycles.

- Defect prevention: detects microscopic anomalies in early stages of the molding process, identifies the root cause (i.e., inadequate pressure, quick cooling), and self-corrects the parameters to prevent further defective parts.

For re-heating/enamelling furnaces: the agentic AI would precisely control zone temperatures, fuel-air ratios, and material throughput to ensure uniform heating/curing, minimize energy use, Therefore, reduce emissions, adapting to varying material sizes or surface finishes without manual input.

-

- Human role: quality inspectors focus on final product details and complex functional tests, while engineers analyze AI insights for new material development or process innovation, rather than constantly tweaking furnace settings.

4. Grinders:

Traditional approach: operators set grinding parameters (feed rate, speed, pressure) and manually inspect finished products, adjusting for wear on grinding media or inconsistent material input.

BeChained’s agentic AI: the agentic AI integrates data from vibration sensors, acoustic sensors, power consumption, and downstream quality checks (i.e., particle size analysis for powders or cellulose slurry). It autonomously:

-

- Optimized grinding: adjusts feed rates, grinding pressure, and rotational speed in real-time to achieve desired particle size distribution, viscosity in pulp slurry, while minimizing energy use and wear on grinding media.

- Adaptive tool wear compensation: detects the subtle degradation of grinding wheels and compensates/balances parameters to maintain output quality, scheduling replacement only when necessary, extending tool performance abnd lifespan.

- Anomaly detection: identifies unusual vibrations or noise, signaling potential material blockages or equipment malfunctions, and takes pre-emptive action (e.g., temporarily pausing feed) to prevent damage.

- Human role: operators conduct periodic physical inspections of the grinding media, handle material loading/unloading, and focus on overall process safety and continuous improvement.

5. Industrial extractor hoods (fume/dust extraction):

Traditional approach: extractor hoods often run at a constant, high speed, wasting energy, or operators manually adjust them based on visible fumes.

BeChained’s agentic AI: the agentic AI uses air quality sensors (for specific pollutants, dust levels), machine operation sensors (detecting when a process creating fumes is active), and energy meters. It autonomously:

-

- Demand-driven ventilation: activates and adjusts fan speeds precisely to the current level of contaminants (i.e. particles) detected, or to the operational status of equipment generating fumes, ensuring optimal air quality with minimal energy consumption.

- Filter life management: monitors filter loading and pressure differentials, predicting when filters need cleaning or replacement and scheduling these tasks, extending filter life and maintaining efficiency.

- Energy recovery optimization: if integrated with heat recovery systems, it intelligently balances extraction needs with heat recovery, further contributing to green operations.

- Human role: facilities managers receive reports on air quality compliance and energy savings, and maintenance teams are alerted to filter servicing needs, freeing them from constant manual monitoring.